How to achieve a net-zero carbon supply chain in 4 steps

What are supply chain emissions?

Consumers, customers, investors, and regulators now expect you to take responsibility for your company’s supply chain emissions - known as ‘scope 3’ emissions. Your entire value chain has a huge impact on the climate, and your sphere of influence extends far beyond your doors.

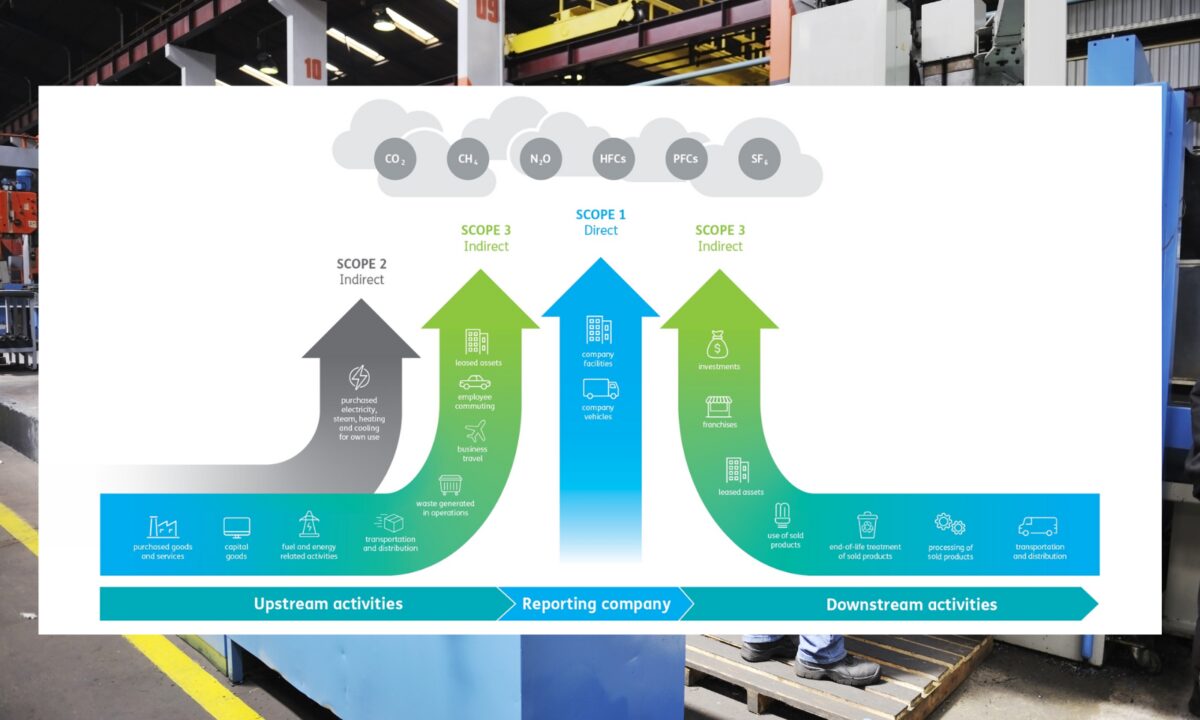

The graphic below represents your value chain.

The middle section is your business operations: ‘scope 1’ emissions. For example, the carbon footprint of your company vans. On the left, you have the ‘upstream’ activities. This includes ‘scope 2’ emissions from the energy you use. So for example, the emissions from a coal power plant that generates the electricity you use in your store. Then you have ‘upstream scope 3’ emissions – the emissions from all the goods and services you buy in your supply chain, along with shipping, and even things like business travel. Finally, you have ‘downstream scope 3’ - emissions from your customers' use of your products.

If you’re thinking, ‘but scope 3 sounds huge and very difficult to keep track of, let alone cut those emissions’, you’d be right. (But we can help – scroll down for tips). Supply chain emissions are 11.4 times higher than direct company emissions on average, according to CDP. As you can imagine, this varies hugely by sector. Energy generators will have smaller scope 3 emissions and huge scope 1 emissions. Retail and hospitality companies meanwhile have the vast majority of their emissions in their supply chains. For retail, supply chain emissions make up a staggering 98% of total attributable emissions, according to McKinsey.

So - in a nutshell - the amount of energy you use to run your fridges will be just a drop in the ocean compared to the enormous impacts caused by the production and transportation of all the goods on your shelves.

Benefits of decarbonising your supply chain

There are huge business benefits to achieving a net-zero carbon supply chain:

- Achieve net-zero climate targets: If you have set science-based targets or a net-zero target, tackling your supply chain is critical to achieving them. You simply won’t get there without bringing your supply chain along for the ride. Acting in line with climate science requires transitioning your whole value chain, and up to 90% of value chain emissions are in the supply chain.

- Reduce vulnerability to climate risks: Through engagement you’ll see where the risks in your supply chain lie, so you can better support your suppliers, and ultimately become more resilient. Whether it’s physical risks like stronger storms and extreme heat, or transition risks such as boycotts from climate-conscious shoppers, climate impacts are beginning to bite. For example, do you know how many of your suppliers’ factories are in high flood-risk zones? In an Accenture survey of CEOs, 69% said climate change is having a moderate or high impact on their business.

- Improve competitiveness by responding to stakeholder demands for climate action: Companies are seeing more and more demands for climate action from their stakeholders, including investors, corporate customers, consumers, and even their staff. 60% of UK workers would choose to work for a company with a clear net-zero plan over one that doesn’t.

- Strengthen relationships with suppliers: Tracking and reducing emissions in your supply chain requires collaboration with your suppliers. Done well, this can strengthen your business relationships which can lead to improved efficiency and resilience. By bringing them on your net-zero journey, you’re helping to future-proof your business and have a positive global impact – together.

How to achieve a net-zero carbon supply chain

It’s challenging work, but you can make progress on your supply chain climate action journey by following these 4 key steps.

1. Carbon accounting

Before you can take action, first you need to take stock of the situation.

Supply chains are complex, so assessing the carbon emissions in your supply chain that can be attributed to your company is a significant piece of work in its own right. Carbon accounting is crucial in order to set a baseline for your emissions, identify where the carbon hotspots are, and track progress toward your goals. Oh - and if you need some support - we have a team of specialist carbon accounting experts who can help.

2. Supplier engagement

This is where the fun begins. You need to engage your suppliers to improve their sustainability practices and reduce emissions. But how?

- First, identify your most important suppliers - those that you spend the most with or those with the highest risks or impacts - and focus on those in the first instance, not hundreds of suppliers that only make a negligible difference to your business.

- Then you need to gather information from these key suppliers about their current environmental performance, usually in the form of a questionnaire or interview.

- Analysing that data can inform a plan to help your key suppliers improve their sustainability practices. This could include training workshops, sharing best practice, support with finance, certifications, or other projects. You will need sight of their carbon emissions and reductions for your own net-zero progress.

- Finally, you include all of this in your climate reporting. Continue to iterate and track progress with regular check-ins and requests for environmental data

And guess what? We can help here too. Our expert supply chain engagement team is ready to support you.

3. Sourcing strategies and procurement policies

To really move the needle on your supply chain emissions, start integrating your response to the climate crisis into your sourcing strategy and procurement policies.

For example, you could include environmental performance questions in your supplier due diligence questionnaires, climate-related clauses in your procurement contracts or carbon reporting specifications in your tenders. Or you could use climate metrics in your scoring of suppliers, alongside cost and quality metrics. And if you are a major retail chain, requiring your key suppliers to set science-based targets would have a huge positive impact.

Another approach is looking at sourcing materials closer to home, as this will naturally reduce emissions from transportation. 21% of companies are localising supply chains to improve resilience, according to an Accenture report.

4. Rethinking business models

If you’ve got this far, you’re doing great. But now it’s time to take things up a notch. It’s time to question the linear business model of ‘take-make-waste’.

Currently, the economy relies on extracting raw resources from the earth and producing goods for consumption which are eventually thrown into landfill. The concept of a circular economy is instead based on the maxims of ‘eliminate, circulate, regenerate’. Waste is eliminated because all outputs are used as inputs to other systems. Products and materials are circulated in the economy, and nature is regenerated.

How can these principles be implemented in your supply chain? Perhaps you could redesign your own-brand products to use more organic, renewable and recycled materials. Maybe you could purchase refurbished equipment or utilise product-as-a-service models.

Taking steps to make your business more circular has many benefits, including reducing costs and unleashing innovation.

Ready to start your journey?

By tackling your supply chain emissions and wider impacts, you’ll improve resilience, reduce costs and strengthen your relationship with suppliers and stakeholders. While you’re at it, you have the power to create positive change that will ripple out through the economy.

If you need help to get started, we have a holistic and flexible approach to supply chain supplier engagement, having supported companies of all sizes, from multinationals to SMEs.

Get in touch today to speak to one of our expert consultants.